Institution and verification of response floor mannequin

Desk 4 displays the blending ratio of 17 experimental teams with sprayed RPC and the outcomes of compressive power, splitting tensile power, and crack sensitivity after curing for 28d. Amongst them, B13–B17 had been the 5 central experimental teams that had been used to judge the soundness of the mannequin.

The response floor mannequin was established utilizing a number of regression evaluation methodology in Design Skilled 12.0® software program. Evaluation of variance (ANOVA)was used to check the accuracy of the regression mannequin and the importance of the influencing elements. Statistical parameters had been used to confirm the accuracy of the mannequin, the precise parameters are proven in Desk 5.

Within the strategy of modeling, non-significant variables had been judged and faraway from the mannequin based on the values of p and R2. Though some fashions weren’t important (p > 0.05), they can’t be excluded contemplating the hierarchy of the fashions and the worth of the mannequin coefficient of dedication R2. Contemplating that the R2 worth of those responses had been all larger than 0.75, correlation between mannequin predictions and measured information was indicated.

The next equations (Eq. (3)–(5)) offers the mathematical fashions for compressive power (R1, MPa), break up tensile power (R2, MPa) and crack sensitivity (R3, % mm − 1):

$$start{gathered} frac{1}{{sqrt {R1} }} = 0.281771 – 0.017046 cdot A – 0.008773 cdot B – 0.075085 cdot C + 0.001429 cdot AC hfill quad quad + 0.000375 cdot A^{2} + 0.000272 cdot B^{2} – 0.035262 cdot C^{2} hfill finish{gathered}$$

(3)

$$start{gathered} lnleft( {R2} proper) = 1.00349 + 0.127853 cdot A – 0.035054 cdot B + 0.361806 cdot C + 0.001874 cdot AB hfill quad quad – 0.038874 cdot AC + 0.033375 cdot BC – 0.002709 cdot A^{2} – 0.001737 cdot B^{2} hfill finish{gathered}$$

(4)

$$start{gathered} frac{1}{{sqrt[5]{R3}}} = 0.306435 + 0.104288 cdot A – 0.11052 cdot B – 0.27082 cdot C + 0.030481 cdot BC hfill quad quad – 0.002568 cdot A^{2} + 0.002484 cdot B^{2} hfill finish{gathered}$$

(5)

the place A is the silica fume/binder ratio, B is the fly ash/binder ratio, and C is the amount content material of metal fiber.

Results of parameters on mechanical properties and crack sensitivity of sprayed RPC

Compressive power

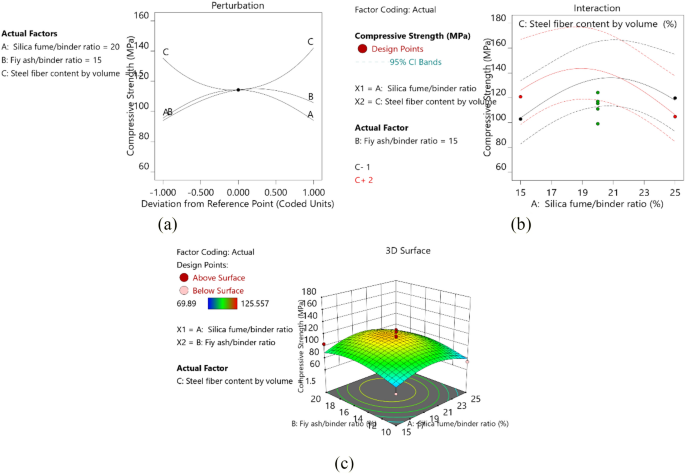

The variance evaluation outcomes of the compressive power mannequin based mostly on the BBD design are proven in Desk 5, and the mannequin equation is given by Eq. (3). The p-values of every issue obtained from ANOVA confirmed that the affect diploma of every issue on compressive power was within the following order: A2 > C2 > B2 > B > AC > C > A. Amongst them, A2, C2and B2 had been important objects, A had an interactive relationship with C.

Determine 4a exhibits the perturbation plot for the response mannequin of compressive power. The outcome confirmed the variations of the compressive power at completely different variables. The compressive power elevated first after which decreased with growing silica fume/binder and fly ash/binder ratios; it decreased first after which elevated with growing content material of metal fiber. Silica fume can densify and homogenize the microstructure of RPC resulting from its filling impact and the excessive pozzolanic response with CH to type C–S–H gel. Fly ash produced a “ball impact” within the strategy of stirring, which performed a task in filling the hole of particles and growing the density of slurry to enhance the compressive power of the matrix. Nevertheless, the loosening impact and the elevated viscosity related to comparatively excessive silica fume content material led to the entrapment of air bubbles and finally lowered the density of the supplies16.

The power of metal fibers was larger than that of sprayed RPC matrix and acted as a bridge within the matrix hinders the event of cracks, and improves the compressive power of sprayed RPC. When the metal fiber content material initially elevated, the compressive power of sprayed RPC progressively decreased, which was completely different from the conclusion of earlier RPC research11. This can be as a result of with the rise of metal fiber content material, the workability of sprayed RPC decreases, which results in the lower of compactness and impacts the compressive power of sprayed RPC. Because the metal fiber content material continued to extend, the typical distance between the fibers decreased. Thus, extra fibers bear the load, ensuing within the discount of the stress between the fibers and the matrix, delaying crack formation and propagation, and growing the power.

Determine 4b exhibits the affect of the interplay between A and C on the compressive power of sprayed RPC. The determine exhibits that when A < 20, the slope of the crimson line is smaller than the black line, indicating that the advance diploma of compressive power is extra delicate to the metal fiber content material of 1. The three-dimensional (3D) plot in Fig. 4c throughout the design boundary confirmed that the response floor determine had a transparent peak, the corresponding contour plot had the very best level, indicating that most compressive power may be achieved throughout the design boundary. The power of sprayed RPC is decrease than that of peculiar RPC, and the affect development of metal fiber on these two supplies is completely different, this phenomenon could also be brought on by the injection course of. Nevertheless, the utmost compressive power of sprayed RPC exceeds 120 MPa, which meets the necessities of conventional RPC for compressive power. The compressive power of sprayed RPC is 71%-140% larger than that of conventional concrete (50–70 MPa)4,40.

Splitting tensile power

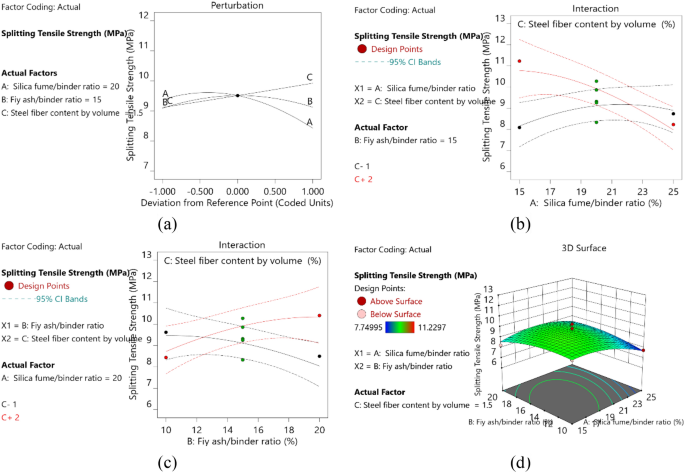

The splitting tensile power prediction mannequin designed based on BBD methodology is proven in Desk 5, and the mannequin equation is proven in Eq. (4). In response to the p-values of every issue obtained from the ANOVA, the diploma of affect of every issue on the splitting power was within the following order: AC > BC > A > A2 > B > C > AB > B2. AC and BC had been important mode objects, and the others weren’t important mode objects.

Determine 5a is the disturbance plot of the splitting tensile power response mannequin. The determine exhibits that the splitting tensile power elevated linearly with growing metal fiber content material, and it elevated first after which decreased with growing silica fume/binder and fly ash/binder ratios. This discovering was resulting from the truth that the pozzolanic response of silica fume elevated the content material of C-S–H gel, decreased the content material of CH, improved the microstructure, and considerably improved the bonding power between the fibers and the matrix. The bond power elevated progressively because the silica powder elevated from 0 to fifteen% and remained comparatively secure when the silica fume content material was 20%. When the content material of silica fume was additional elevated to 25%, the bond power decreased17. The bond power of the fiber-matrix interface was offered by a chemical bond, which anchored mechanical pressure and friction forces associated to fiber ends. Because the bond power decreased, the fibers had been extra more likely to be pulled out from the matrix, and the splitting tensile power decreased.

The slope of A in Fig. 5a was larger than that of B, which indicated that the splitting tensile power was extra delicate to silica fume/binder ratio than to fly ash/binder ratio. As necessary mannequin objects, the affect of AC and BC had on the splittiing tensile power of specimens was proven in Figs. 5b, c. With the change of metal fiber content material (C), the affect of silica fume/binder ratio (A) and fly ash/binder ratio (B) on the splitting tensile power confirmed completely different tendencies. When C = 1, the splitting tensile power elevated with growing silica fume/binder ratio and decreased with growing fly ash/binder ratio. When C = 2, the splitting tensile power decreased with growing silica fume/binder ratio, however elevated with growing fly ash/binder ratio. A transparent highest level may be seen from the 3D plot in Fig. 5d, indicating that the utmost break up tensile power may be obtained throughout the vary of variable design.

Crack sensitivity take a look at

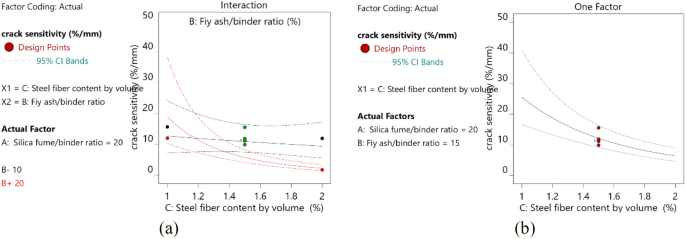

The outcomes of ANOVA of BBD-based crack sensitivity mannequin are proven in Desk 5, and the mannequin equation is given by Eq. (5). In response to the p-values of every issue obtained from ANOVA, the affect diploma of every issue on crack sensitivity was within the following order: C > BC > B > A2 > B2 > A. C, BC, B, A2, and B2 had been important phrases, A was an insignificant time period, and B had an interactive relationship with C.

In response to p-value, metal fiber content material had essentially the most important impact on crack sensitivity, which was far larger than different elements. Metal fiber was conductive; thus, present was transmitted by contacts between metal fibers or electrical tunnels forming conductive paths. Determine 6a exhibits that the crack sensitivity decreased with growing variety of metal fibers. This discovering was completely different from these obtained in earlier research31, and such distinction could also be because of the addition of too many metal fibers in sprayed RPC, making it tough to stir and resulting in uneven fiber distribution. When RPC was sprayed into the mildew, the hole across the fiber elevated, thereby decreasing {the electrical} contact between the fiber and the matrix. In consequence, the crack sensitivity decreased with growing metal fiber content material. Determine 6b additionally exhibits the interplay between B and C. When C = 10, the content material of metal fiber had little impact on crack sensitivity. When C = 20, the crack sensitivity decreased sharply at first after which decreased slowly with growing metal fiber content material.

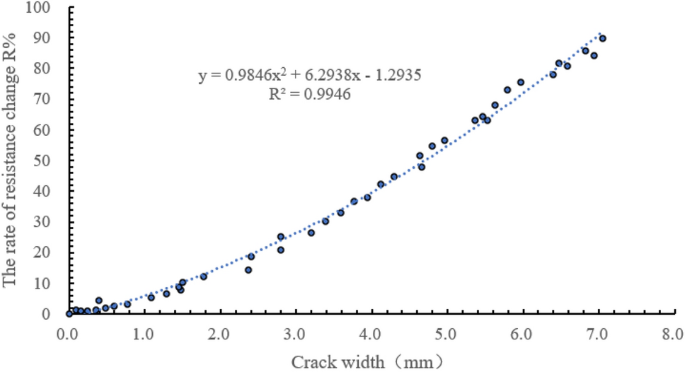

All concrete samples confirmed comparable tendencies in crack sensitivity, so one group was chosen for evaluation. Determine 7 exhibits the connection between crack width and the speed of resistance change when A = 15, B = 10, and C = 1.5. The determine exhibits that the resistance change was not apparent earlier than the crack appeared, however when the crack appeared, the resistance change fee started to vary. With growing measurement of the crack, the speed of resistance change additionally elevated progressively. This was as a result of with growing crack width, the conductive path shaped between the fiber and the matrix was progressively damaged, and the tunnel impact was weakened, resulting in the rise of resistance.

Multi-objective optimization of response

Desk 6 exhibits the usual setting of variable multi-objective optimization utilizing response floor methodology to acquire the very best impartial variable setting to optimize the very best mechanical properties and crack sensitivity of sprayed RPC. The variables had been optimized synchronously based mostly on the expectation operate, and the optimum worth of the impartial variables was obtained when the silica fume/binder ratio was 15%, the fly ash/binder ratio was13.203%, and the amount content material of metal fiber was 2%. The optimum response worth might be obtained underneath this combination ratio. Particular predictive values are proven in Desk 7. These values had been achieved at a desirability worth of 75.4%. The goal values could also be set with completely different weights and significance relying on the anticipated setting of the goal response. The compressive power was set in a spread, as a result of the optimized compressive power of 119.107 MPa met the necessities of conventional RPC.

![[Real or Hoax] Shocking Price, Shark Tank and Side Effects Explained 2021? – Business](https://nutritioncenter.extremefatloss.org/wp-content/uploads/2021/12/1f449.png)