[ad_1]

Bent bamboo springback habits

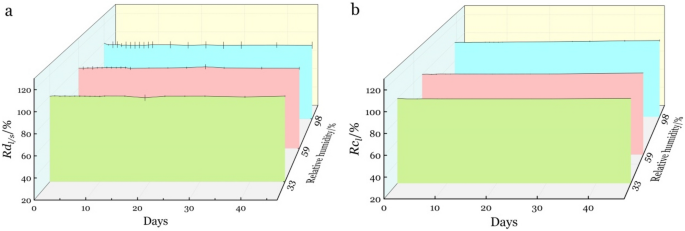

Altering of Rdl/s and Rcl underneath completely different relative humidity with time is proven in Fig. 3. Chord size and ratio of lengthy diameter to quick diameter modified inside 2% after 47 days underneath 33% RH, 59% RH, 98% RH, which point out that bent bamboo springs again little and has a excessive dimensional stability underneath low or excessive humidity situations.

Containing giant quantities of silicon compounds19, bamboo has a clean and excessive hydrophobicity floor20 which resulted in sustaining the bamboo bent stability. We discovered restricted dimensional modifications of Rdl/s, Rcl with time due to viscose deformation restoration underneath excessive humidity within the biomaterial bamboo21.

Radial distribution of density, MFA and MOE

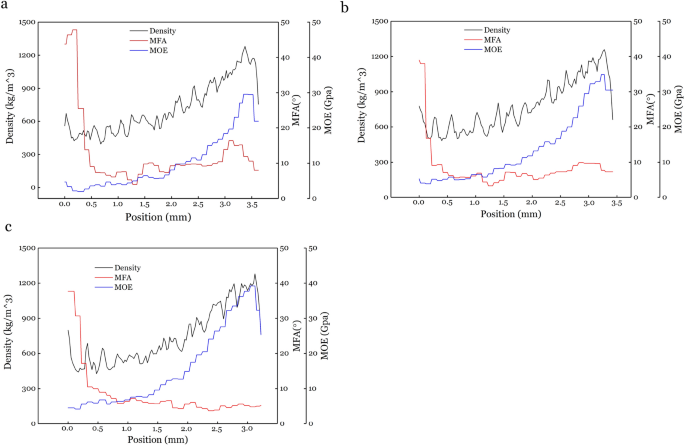

Radial distribution of density, MFA and MOE on C, N and T of bending bamboo part are proven in Fig. 4. Outcomes present that the distribution alongside radial of density, MOE and MFA is analogous, which MOE elevated from bamboo yellow layer (YL) to bamboo inexperienced layer (GL), whereas MFA is way greater in YL in comparison with GL for all three samples.

Density distribution alongside radial course

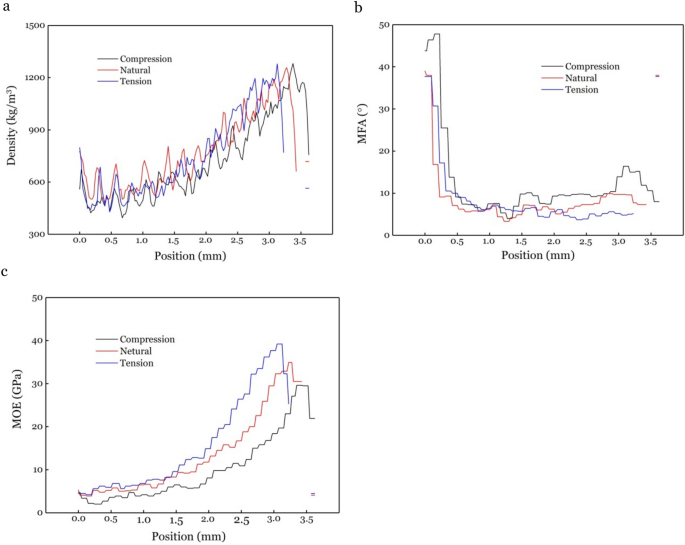

Density distributions alongside radial course from YL to GL for C, N and T pattern in bending bamboo are confirmed in Fig. 5a. The same tendency of accelerating density from YL to GL could be present in all three samples, with the density distribution of the C pattern decrease than the N pattern. Arithmetic imply density values for C, N and T samples are calculated as 720.38 kg/m3, 775.97 kg/m3 and 742.75 kg/m3 individually, indicating that the imply density of C and T samples decreased in contrast with N pattern in bending bamboo. The imply density of compression and pressure wooden additionally differed from pressure wooden, which confirmed constructive correlation between density and pressure wooden fibres proportion22,23. Density typically correlate strongly with wooden shrinkage24. The lower of density in compression and pressure half was useful in enhancing the dimensional stability of bent bamboo.

Pressure would include rising stress when materials expertise any type of exterior pressure. In some instances, stress isn’t giant sufficient to provide apparent deformation, however it’s troublesome to exactly measure stress and pressure inside wooden, bamboo, or different supplies. Normally, when there may be giant stress, pressure is seen and could be measured extra precisely. Bending is a type of apparent pressure with the fabric experiencing bending load finally leading to bending part deformation25,26. Tube part would change from round to elliptical after bending27, which is a perform of various levels and types of pore deformation. Following pore deformation, part density redistribute (Fig. 5a), which lead to stress redistribution on the bending part of interior, center and outer aspect28.

MFA distribution alongside radial course

MFA is outlined as an inclination of microfibrils from the longitudinal axis, which play an vital position in figuring out the ultimate mechanical properties of bamboo29 and wooden30. There are a variety of components which can have an effect on MFA in wooden or bamboo, corresponding to ages29,31, species32, and places in cross-Sect. 31. Though earlier analysis has been carried out on MFA distribution alongside radial course by selecting some factors on the cross part31, little analysis has been completed to look at the continual distribution of MFA alongside radial course.

MFA distributions alongside radial course at a 0.1 mm decision for pattern C, N and T are proven in Fig. 5b. The MFA had been highest (38° ~ 48°) in about 0.2 ~ 0.5 mm close to YL, adopted by sharp lower (10° ~ 4°) in distance of 0.5 ~ 1.8 mm from YL. A small improve was noticed within the final 1 mm for C and N, besides T. Arithmetic imply MFA values for C, N and T are calculated as 12.5°, 8.3° and eight.3° in the entire bamboo wall thickness. Though MFA confirmed almost similar arithmetic imply worth in samples N and T, the worth of the outer half bamboo wall close to the inexperienced half skilled the best bearing power32. The C, N and T close to the GL had been calculated as 11.0°, 7.5° and 5.0° with bigger distance between the three MFA distribution.

MFA performs an vital position in bodily properties, corresponding to bending power, Younger’s modulus29, and can be an efficient character to point out bamboo inside stress altering. Earlier research have proven a lower in MFA with a rise in pressure stress32, and a rise in MFA with a rise in compression33. This agrees with the results of this examine that reveals these modifications primarily occurred within the half outer bamboo wall. A lower in MFA is represented by higher alignment of cellulose alongside axis course, which resulted in greater tensile power34. Likewise, a rise in MFA is represented by a rise longitudinal compression, which resulted in higher bendability35. This altering tendency of the MFA within the outer half T and C wall point out that bamboo has good bending stability.

MOE distribution alongside radial course

Supplies undergo inside stress when bending is carried out with exterior loading pressure. Nonetheless, when the exterior pressure is eliminated, there can be a springback tendency for the bending materials attributable to the inside stress. This bending springback property could be altered by curvature radius36,37, bending technique37, and the mechanical properties of the bending materials38,39. As one of the vital vital mechanical properties, MOE has a damaging correlation with bending springback property for bending members40,41.

Uneven MOE distribution for C, N and T elements alongside radial course is proven in Fig. 5c. The MOE rises with rising distance from YL to GL for these three samples. The modifications in MOE is comparatively small at first, adopted by giant modifications within the center and finally dropping once more within the final 0.2 mm. MOE worth differs so as of T > N > C, which arithmetic imply worth calculated as 15.72 GPa, 13.58 GPa, and 10.14 GPa, respectively. Arithmetic imply values of T, N and C had been 6.73 GPa, 6.13 GPa, and 4.22 GPa for the primary half tube wall (close to YL) whereas 24.44 GPa, 20.81 GPa and 15.90 GPa for the latter half (close to GL). There’s a bigger distinction on the latter half tube wall than the primary half tube wall, whereas the latter half tube wall bears the next stress than the primary half tube wall throughout bending.

Our outcomes present that bending has an impact on MOE of the bending part. The MOE worth shifts for each pressure and compression elements in contrast with impartial half (Fig. 5c), which is probably going resulting from microstructural modifications underneath bending stress. For instance, fiber orientation and diploma of crystalline orientation would improve throughout pressure, whereas lower throughout compression34,42, which has similarities to a rise and a lower in MOE throughout the pressure and compression section, respectively43,44. The springback in bamboo is attributable to a number of components: (1) uneven distribution of stress alongside cross part (there’s a greater stress within the exterior half tube wall than the within)41; (2) the upper MOE within the exterior tube wall than the within; and (3) the upper MOE within the first half bamboo tube wall than the latter half. These traits could be useful to scale back springback for the bending bamboo.

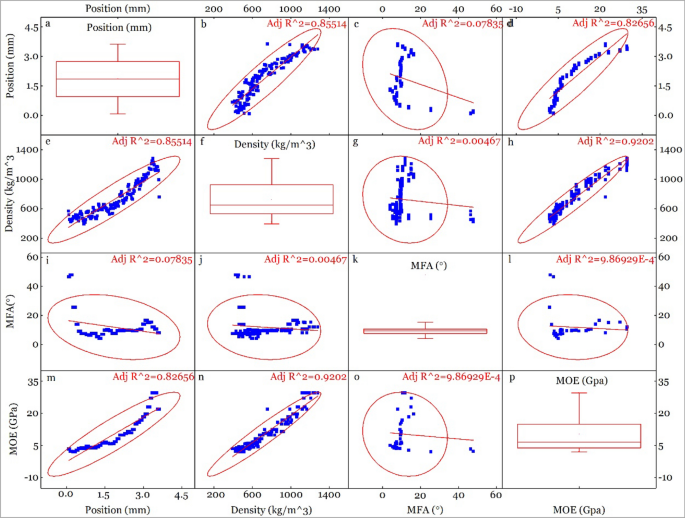

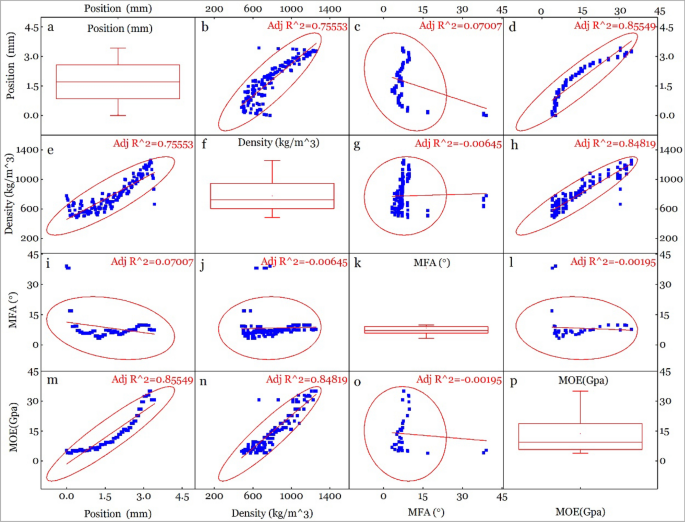

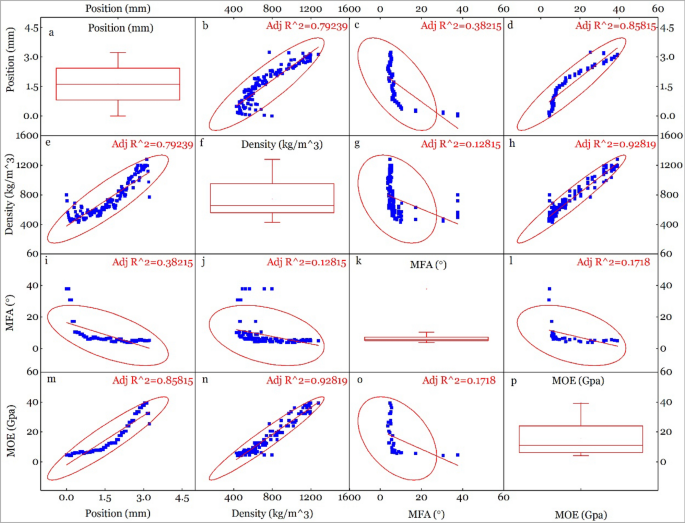

Correlation between place, density, MFA & MOE

Correlation between place, density, MFA & MOE of compression (Fig. 6), impartial (Fig. 7) and pressure (Fig. 8) elements is discovered. It reveals a excessive correlation between place and density (R2 = 0.85514 for C, 0.75553 for N and 0.79239 for T), place and MOE (R2 = 0.82656 for C, 0.85549 for N and 0.85815 for T), MOE and density (R2 = 0.9202 for C, 0.84819 for N and 0.92819 for T). The excessive correlation between place and density, place and MOE is attributable to the radial distribution of density (Fig. 5a). Density is a crucial determinant to the power of bamboo or wooden18,45, which made it a excessive correlation with MOE.

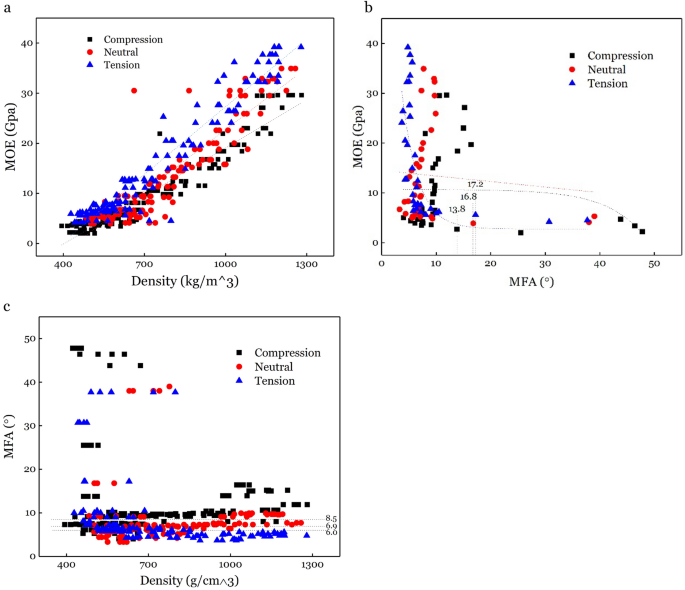

MOE is among the most vital mechanical properties for bending purposes, which is influenced by density46, MFA47,48. MFA and density can have completely different impact on MOE, and is a perform of species kind. For instance, MFA and density collectively account for 96% of the longitudinal MOE variation in Eucalyptus delegatensis49, whereas MFA and density, individually account for 87% and 81% of the variation, respectively50. Evaluation of the connection between MFA and density have proven damaging correlation (− 0.59) in Pinus taeda L.51. Likewise, MFA and MOE confirmed bigger variation alongside radial course (400 kg/m3 ~ 1400 kg/m3 for density, 5° ~ 48° for MFA and a couple of GPa ~ 40 GPa for MOE (Figs. 6, 7 and 8) than wooden, indicating that correlations between density, MFA and MOE for the C, N and T half in bending bamboo, would possibly differ with wooden.

We discovered an excellent line correlation between MOE and density as proven in Figs. 6n, 7n, 8n and 9a, With proportion of variance of R2 = 0.9202, 0.84819 and 0.92819 for C, N and N half respectively(Figs. 6, 7, 8, 9). This proportion of variance is greater than R2 = 0.54 in moso bamboo, the place density and MOE had been estimated utilizing drilling resistance approach and static bending take a look at; respectively52. Likewise, it present R2 = 0.47 in white oak, the place density and MOE had been analyzed utilizing SilviScan, and R2 = 0.70 in E. delegatensis, the place density and MOE had been estimated utilizing SilviScan and vibration testing, respectively49. Slope of MOE to density is0.03202, 0.04097 and 0.04501 for compression, impartial and pressure half; respectively, which signifies that MOE is extra delicate to density throughout pressure than compression.

Whereas we discovered a powerful linear correlation between MOE and density, there was a damaging correlation between MOE and MFA as proven in Fig. 9b. Our outcomes present the R2 = 0.42835 for pressure half when the expdec1 perform was used. Nonetheless, the correlation was low to meaningless in impartial (R2 = − 0.00937) and compression (R2 = 0.04631) samples, which point out that MOE is extra delicate to density in pressure half in comparison with impartial and compression half.

We additionally discovered an “affect diminishing” level, the place MOE doesn’t scale back additional past the sure level of MFA. The “affect diminishing” level seems to be 16° in three sorts of eucalyptus species (plantation-grown E. globulus, E. nitens and E. regnans)50. On this examine, the “affect diminishing” level of the bending bamboo various as place of the part modified. The “affect diminishing” factors had been 17.2°, 16.8° and 13.8° for pressure, impartial and compression half individually.

A earlier examine has proven damaging correlation between MFA and density in ineucalyptus globulus (r = − 0.66) and Pinus taeda L. (r = − 0.59)53. On this examine, there was no apparent linear correlation between MFA and density as proven in Figs. 6j, 7j, 8j and 9c. With some particular excessive MFA worth factors when density is beneath 800 kg/m3, MFA approaches to be fixed when density modified. After eradicating the “affect diminishing” and above factors, the MFA algebra common worth had been 6.0°, 6.9° and eight.5° for pressure, impartial and compression half, respectively. This reveals that MFA declined underneath pressure and rises underneath compression, which is in keeping with MFA altering tendency in pressure and compression in comparison with regular wooden54,55.

[ad_2]

Source link