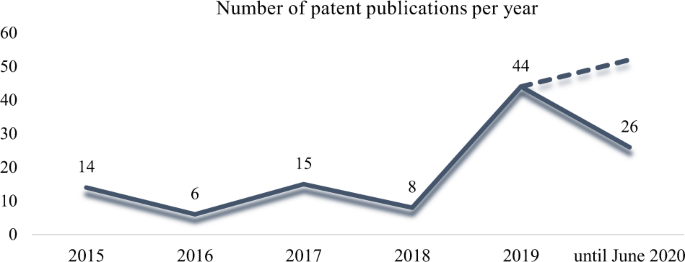

In complete, 1036 patent functions had been discovered from January 2015 to June 2020 within the IPC A23J1/14 subgroup. The ultimate pattern counted on 113 patents after screening and eligibility standards utility. By evaluating the variety of plant-based beverage functions within the final 5 years, it was attainable seeing a rise on this quantity again in 2019: 44 patent functions (Fig. 3). Noteworthy, 26 patents had been utilized as much as June 2019, and this discovering is indicative of upward tendency estimated to the variety of functions within the following years. Such an estimate may be confirmed by each the present plant-based beverage consumption development1 and populations’ elevated curiosity in protein-rich merchandise9.

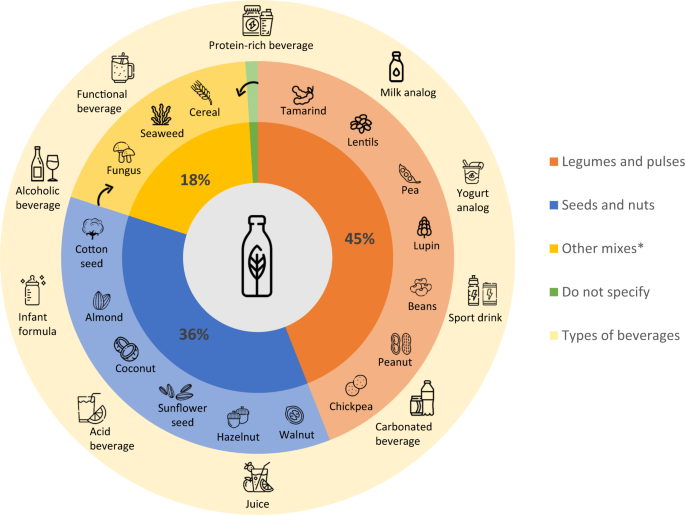

Patents had been divided into three completely different teams, specifically: “seeds and nuts”, “legumes and pulses”, and “different mixes”, since A23J1/14 subgroup is expounded to leguminous, vegetable seeds, press-cake, or oil-bearing seeds (Fig. 4). Based mostly on the outcomes, most patents are associated to legumes and pulses utilizing (45%), adopted by seeds and nuts (36%), different mixes (18%), and patents that didn’t specify their uncooked supplies (1%).

Legumes and pulses examples are highlighted in orange; seeds and nuts, in blue; different mixes, in yellow; don’t specify, in inexperienced; beverage sorts are expressed in mild yellow. *Different mixes embrace patents that used “legumes and pulses” and/or “seeds and nuts” and/or different elements, akin to cereal, seaweed, and fungus.

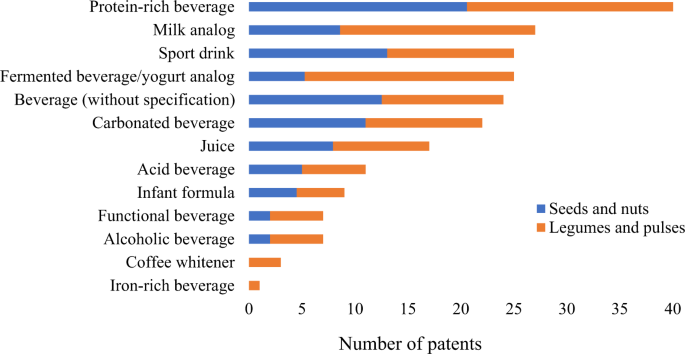

Most patents (n = 40) talked about their applicability to protein-rich beverage manufacturing. This discovering was anticipated because of the present demand for this class of product9 (Fig. 5). Milk analog (n = 27) and fermented beverage/yogurt analog (n = 25) come proper in sequence, and it corroborated shoppers’ elevated curiosity in alternate options to dairy merchandise1. Sports activities drink (n = 25), carbonated beverage (n = 22), juice (n = 17), and acid beverage (n = 11) had been additionally usually addressed in patents, and this discovering meets the present want of utilizing plant proteins at completely different pH ranges with out compromising the options of ultimate merchandise.

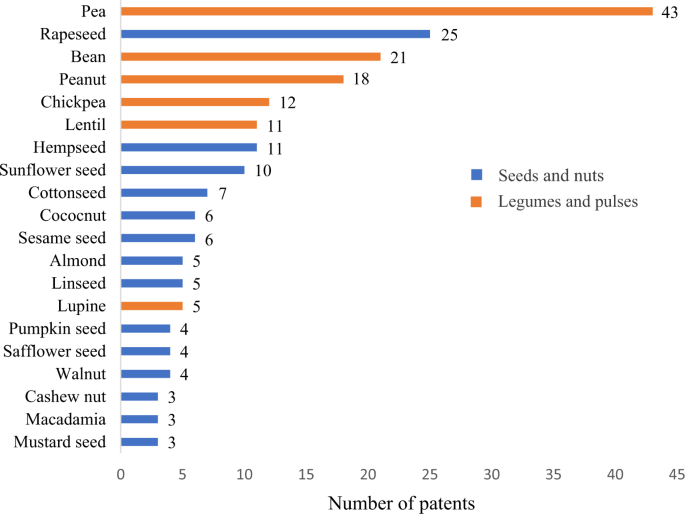

Determine 6 reveals the preferable uncooked supplies for patent candidates. It is very important level out that the sum of recorded outcomes will likely be increased than the full variety of patents chosen for the present research if one takes into consideration that some patents used multiple uncooked materials on its applicability. Essentially the most preferable uncooked supplies chosen by patents candidates had been pea, rapeseed, and bean.

Seeds and nuts are represented in blue, whereas legumes and pulses are represented in orange. *The identical patent can use multiple uncooked materials as preferable; **In complete, 13 patents used different uncooked materials sorts, akin to cereal, seaweed, or fungus, in addition to utilizing legumes, pulses, seeds, or nuts; ***Three (3) patents didn’t specify the used uncooked supplies; ****Brazil nut, Camelina seed, Castor bean, Chia seed, Cocoa seed, Fenugreek, Ginkgo biloba seed, Pepper seed, Perilla seed, Physalis seed, Pistachio, Primula seed, Samara seed, Sea buckthorn seed, Snackegourd seed, Tamarind, Thistle seed, Tomato seed, Tung seed, Turnip seed, and Wisteria had been cited as preferable uncooked materials by one patent. *****Alfalfa, Broccoli seed, Camellia seed, Grape seed, Hazelnut, Moringa oleifera seed, and Locust bean had been cited as preferable uncooked materials by two patents.

Seeds and nuts

Seeds are of nice financial and organic significance if one takes under consideration that they’ve a excessive oil and protein content material, and huge starch reserves. Nuts from timber are really useful as a part of a nutritious diet given their protein, phytochemicals, micronutrients, and unsaturated fats content material14. Seeds and nuts may be the uncooked materials for oil manufacturing, which is commonly extracted by chilly urgent—this course of generates a by-product often called “press-cake”; or it will also be extracted with natural solvents—on this case, the residue is named “meal”26. The worldwide 2018/2019 oilseed manufacturing reached 600.47 million metric tons27, therefore enormous quantities of oil extraction by-products can be found. Though press-cakes and meals are sometimes discarded as waste or used as elements for feed supplementation, they’re good protein, fiber, and bioactive compound sources26,28. Furthermore, due to the growing demand of protein merchandise, such waste sorts are a possible various supply for protein extraction5. Nonetheless, the oil extraction process usually decreases protein solubility29 and it compromises its use in drinks. Thus, most of the herein-reviewed patents had been associated to strategies utilized to extend or protect the solubility of proteins extracted from muffins and meals. Moreover, relying on the uncooked supplies, meals and press-cake usually possess undesirable quantities of compounds that lower protein digestibility, akin to fibers and antinutritional components5—such a matter is continually mentioned in most patents as nicely. Furthermore, the preferable protein extraction strategies had been associated to the protein precipitation utilizing an alkaline, acid, or salted answer, adopted by a particular filtration and drying approach (Desk 1).

Based mostly on the outcomes, rapeseed was probably the most used seed, because it was the preferable uncooked materials in 25 patents (Desk 1). Rapeseed ranks second place of the most important oilseed cultivated worldwide, it simply loses its place to soybean30. Rapeseed and “canola” are the frequent names given to species Brassica napus L., Brassica rapa L., and Brassica juncea L; nonetheless, the title “canola” solely refers to rapeseed varieties presenting lower than 2% erucic acid and meal accounting for lower than 30 μmol/g complete glucosinolates. The crude protein in rapeseed meals ranges from 35 to 40%. Not less than 40 completely different protein fractions may be discovered on this complete, however cruciferin, napin, and oleosin are probably the most investigated ones5. Cruciferin and napin are the principle storage proteins, they account for 60 and 20% of the protein content material in rapeseeds, respectively26. Oleosin presents structural proteins related to oil elements31. Though rapeseed has decrease sulfur-amino acid ranges5, canola meal has higher amino acid profile than soybean. However, canola proteins current many antinutritional components, as amongst them glucosinolates, phenolics, phytates, in addition to a considerable amount of fibers able to compromising digestibility, shade, style, and physicochemical properties29. This discovering explains some authors’ curiosity in patenting innovations that may remedy these downside. Patents WO2019110556 (A1) and EP3481220 (A1) clarify learn how to isolate inherently candy rapeseed proteins presenting low content material of antinutritional components and excessive solubility, which can be utilized to cut back the quantity of sucrose in drinks, and concurrently enhance protein content material within the product. Likewise, BRPI0917295 (A2) supplies rapeseed protein isolate that’s soluble and steady not solely in acid pH but in addition at increased temperatures. For the time being, Burcon® is the one producer of high-purity canola protein on the planet32,33, regardless of the potential of this uncooked materials.

Hemp (Hashish sativa L.) was the preferable uncooked materials in 11 patents (Desk 1). It’s primarily cultivated for the economic use of its seeds, fibers, oil, and meal34. For the time being, hemp is on the mainstream, since it’s a sustainable crop that doesn’t require fertilizers, herbicides, and pesticides35. Hemp may be legally cultivated for industrial functions in most international locations worldwide, when it has as much as 0.3% of its foremost psychoactive compound: delta-9-tetrahydrocannabinol (THC)26. Hemp seeds are wealthy in phytosterols (ω-3 and ω-6) and have ~25% of proteins in its dry weight35. Roughly 65% of the full hemp protein includes a single globular storage protein: edestin; then again, the albumin fraction consists of 25% of storage proteins26. Though it has low lysine content material15, hempseed protein incorporates all of the important amino acids and accounts for low quantity of antinutritional components, akin to trypsin inhibitor; due to this fact, it presents high-degree digestibility35. Hempseed protein may be acceptable for athletes and infants, for instance, given their high quality. Patent BR112015001964 (A2) supplies a hempseed protein that’s utterly soluble in acid drinks (decrease than 4.4 pH), with out the necessity of stabilizers or components. Thus, it may be used for protein fortification in delicate and sports activities drinks, in addition to in different aqueous methods. Equally, CN110150391 (A) disclosed a canned beverage for athletes made with hempseed albumins, which is even higher absorbed by the organism than the entire hempseed protein. US2015079235 (A1) proposed hempseed protein utilizing as the principle ingredient in another toddler formulation, which may be both powdered or liquid. Presently, Axiom Meals® and Good Hemp®, which provide merchandise with 58 and 85% purity, respectively, are among the many hempseed protein suppliers on the planet36,37. Additionally, Manitoba Harvest® and LeanHemp® are manufacturers specializing in the hempseed protein complement section38,39.

Ten patents used Sunflower (Helianthus annuus L) as preferable uncooked materials (Desk 1). This species is likely one of the most cultivated oilseed crops40; its seed meal can attain 40% protein content material when it’s mechanically extracted, and 50% protein content material when the oil is extracted with natural solvents5. Roughly 85% of the full protein content material in sunflower seeds is discovered within the type of storage proteins (11S helianthinin globulin and 2S albumins)26. Globulin content material varies from 40 to 90%, whereas albumin charge ranges from 10 to 30% of the full protein present in seeds. It’s attainable observing variations within the ratio of those protein fractions since three completely different sunflower seed sorts are majorly cultivated—they’re used for oil manufacturing, human and pet consumption, and ornamentation5. Regardless of its low lysine content material, sunflower meal stays a superb protein supply, given its excessive digestibility and smaller variety of antinutritional compounds41. Though sunflower seed proteins have low performance, such a function is intently linked to denaturation brought on by heating at oil extraction, moderately than to native proteins themselves. Furthermore, phenolic compounds present in sunflower seeds, akin to chlorogenic acid, can crosslink with proteins and alter its shade, performance, and bioavailability. Nonetheless, chlorogenic acid can also be helpful for human well being40 and may be fascinating when it’s correctly extracted from sunflower seed meal. Patent CN109354574 (A) improved a way by utilizing supercritical carbon dioxide extraction to organize chlorogenic acid and protein powder from sunflower seeds, in separate. This powder is an attention-grabbing uncooked materials for making synthetic milk and drinks as a result of its delicate taste. Equally, FI128029 (B) addresses a sunflower seed protein with enhanced solubility and low phytate content material. Its powder is an acceptable ingredient for dairy alternate options. Following performance enhancements, BR112018070543 (A2) used enzymatic therapy, heating, fermentation, and stress therapy to extend the techno-functional and organoleptic properties of sunflower seed protein, which is beneficial as a drinks’ complement. Presently, Biotechnologies® is the one world sunflower seed protein producer whose product has greater than 80% purity42; Nonetheless, it’s attainable discovering different suppliers whose merchandise attain about 50% protein content material, amongst them one finds Austrade Inc® and ETChem[®43,44.

Based on the results, cottonseed was the preferable raw material in seven patents (Table 1). Fiber is the most common product made out of cotton; however, cottonseed has great potential as protein source, for both animal and human consumption45. Cottonseed meal has ~30 to 50% total protein46. Arginine has the highest content (22–34%) of essential amino acids, whereas cysteine accounts for the lowest one (1–2%)47. Cottonseed meal is a good protein source for ruminants, but it is not appropriate without treatment for monogastric animals, including humans, who do not tolerate high fiber contents and antinutritive compounds, such as gossypol, phytin, and cyclopropane fatty acids46. In total, 80% of defatted cottonseed is used as substrate for edible mushroom crops or as fertilizer, but only 5 to 10% of it is used for animal feeding purposes, a fact that causes huge protein waste48. The appropriate extraction of these proteins from the meal is a feasible option to solve this problem. Patents HUE033952 (T2) and PL2498620 (T3) disclosed enhanced methods to produce high-quality protein concentrates and isolates from oilseed meals, including cottonseed, which has incredibly low fiber content and antinutritional factors. These concentrates and isolates are useful as powdered milk analog or to increase protein content of juices, soft drinks, sports drinks, and beverages in general. RU2018129466 (A) disclosed a method to extract cottonseed proteins that can fortify beverages as well. When it is compared to other patents, it also has the advantage of not presenting beany or grassy flavor notes. Nevertheless, so far, cottonseed protein suppliers in the market only provide to animal feeding, they still do not focus on human nutrition.

Legumes and pulses

Legumes are the most consumed staple food after cereals, since they are a low-priced source of nutrients, mainly of proteins; therefore, they are seen as “meat for poor men”14,15. In botanical terms, legumes belong to the family Leguminosae, which also comprises pulses. All pulses are legumes, although not all legumes are pulses. Based on the Food and Agriculture Organization definition, pulses are only dried edible leguminous presenting low oil content. Consequently, legumes harvested in green forms, such as green beans and green peas, are not included in this group. Furthermore, soybeans and peanuts, which are oil-rich, are also excluded from it. Lastly, crops used for sowing purposes, such as alfalfa and clover, are not pulses49. Pulses are good energy, fiber, vitamin, mineral, and bioactive compound sources, and besides, ~30% of pulses’ dry bases are proteins50. In addition to their nutritional importance, pulses have the good nitrogen-fixing capacity and are beneficial to soil fertility and the environment51. Some native pulses and legumes’ proteins are promising to the beverage industry due to their functional features, such as solubility, emulsifying, and foaming proprieties50. However, depending on the species and on the protein extraction method, beverages made with these proteins also show beany flavor, bitter taste, or sandy mouthfeel4,14,15 —these factors limit their acceptance by consumers. Another disadvantage of these proteins lies in the fact that different procedures must be followed in order to reduce antinutritional factors and nonprotein compounds from pulses and legumes. Although, isolate proteins extracted from legumes and pulses remain in the mainstream of researchers and patent applicants as they are an economical, ecological, nutritive, and gluten-free raw material used to enrich products50. Enzymolysis and protein precipitation using an alkaline, acid, or salted solution were the preferable protein extraction methods applied, commonly followed by a specific filtration and drying technique (Table 2).

Pea was the most used raw material in the herein assessed patents, it was the preferable raw material in 43 patents (Table 2). Pea is an ancient crop widely grown in different countries50. At the moment, pea stands out for its properties similar to those of soybean protein; therefore, it presents great potential to replace this protein, since soybean is often associated as allergenic13. Emulsification, foaming, and gelling are some of these properties, for instance14. Pea has 23 to 31% total protein, and 50 to 85% are globulins (legumin, vicilin, and convicilin), while 15 to 25% are albumins50. Arginine, phenylalanine, leucine, and isoleucine are among the essential amino acids commonly found in the globulin proteins, whereas tryptophan, lysine, threonine, cysteine, and methionine are found in the albumin ones52. Overall, the amino acid profile is well-balanced and the high lysine content is notable13. Even so, the bitter taste intrinsic to pea flour produced through dry milling can be transferred to final products. Patent CA3067593 (A1) disclosed methods to produce pea flour, concentrate or isolate with low nonvolatile flavor compound contents, specifically bound saponin, in order to solve this problem. This process consists of steam cooking and drying a raw pea slurry to produce a bitterless flour that can be used in beverages. Similarly, FR3070831 (A1) used sodium citrate and heating to partially or fully reduce the bitterness of pea protein compositions. Fermentation can also improve flavor; therefore, yogurt-like products are a good option to be made of pea protein, as proposed by CN109566747 (A). Pea protein has been consolidated in the market by world suppliers such as Roquette®, Burcon®, Axiom Foods®, AMCO Proteins®, Ingredion®, Cargill®, and Farbest[®53,54,55,56,57,58,59. Pea protein milk and yogurt are already available and provided by Ripple® and Siggi’s®, respectively60,61.

Based on the results, bean was the preferable raw material in 21 patents (Table 2). Common beans belonging to the family Leguminosae and to genus Phaseolus account for one-third of global pulses production62. There are more than 14,000 known different common bean cultivars. Peculiarities of local culture, agriculture, and history influence the mostly consumed beans. Variations on beans’ size, shape, and colors can occur, as well as on their composition and physicochemical features, but these differences tend to be nonsignificant63. Overall, dry beans are an important source of proteins—its protein rate ranges from 16 to 33%50. Albumins account for up to 10–30% of total protein content on dry weight basis, whereas globulins account for 45–70% of it52. Phaseolin and lectin are other important protein fractions found in beans50. Although the protein content in beans is significant, it shows some drawbacks, since beans have methionine as limiting amino acid and antinutritional factors are observed in them62. These factors can be removed from pulses through a simple fermentation process; consequently, it increases the quality of pulses’ proteins15. Patent JPWO2014156549 (A1) disclosed methods to produce a gel by adding alkali metal ions to mung bean protein and by fermenting it. The produced composition can be used as yogurt analog. Similarly, CN106261782 (A) used biological mung bean fermentation to separate protein, starch, fiber, and slurry, and to provide different products, such as instant tablet beverage and fermented drink. Once more, to reduce antinutritional factors, KR20190087654 (A) developed a bean protein presenting low phytic acid content by using calcium salt to precipitate it. At the moment, It is possible finding 80% purity mung bean and fava bean protein suppliers, as among them one finds ETProtein® and Atura®, respectively64,65. The brand Green Boy® also offers powdered proteins extracted from these same bean species66,67. Nancy’s® produces yogurts with different flavors, all made of fava bean protein68.

In total, 18 patents were related to peanut’s use as preferable raw material (Table 2). Peanut accounts for 11% of the global protein supply69; it has been gaining more popularity due to its resistance to climate changes8, as well as because it is a cheap source of high-quality protein. Deffated meal, which is a by-product by the peanut industry, has ~50–55% protein and balanced amino acid profile70; therefore, it can be easily used as raw material to produce protein isolates71. Peanut proteins are often classified as albumins and globulins. Arachin and conarachin are the main globulins, and both of them are rich in lysine, tryptophan, tyrosine, and phenylalanine69. Peanut protein is often nutritionally comparable to animal protein72, mainly after fermentation, since this process increases its l-lysine, l-methionine, and l-tryptophan contents1. However, its allergenicity69 and poor functional proprieties hamper peanut protein use by the food industry70. Different treatments, such as chemical, physical, or enzymatic methods, have been applied to expand peanut protein functionality. Patent CN106260496 (A) disclosed an improved ultrasonic treatment applicable to peanut protein that provides better solubility, higher yield, and efficiency, as well as environmental protection, when compared to the state of the art. FR3072002 (A1) addresses a stable gel that can be produced by improving peanut protein solubility followed by adding transglutaminase to it. This gel is highly useful to produce yogurts. According to CN106367196 (A), it is possible obtain peanut protein that presents stability in beverages by preventing its denaturation during the extraction process. High-purity peanut protein isolates or concentrates are not in the market yet; however, deffated peanut powder is already provided by ETChem® and Peanut Butter & Co®, for example73,74.

Based on the results, chickpea was the preferable raw material in 12 patents (Table 2). It is the second mostly produced legume worldwide and its protein amount ranges from 15 to 30%. Globulins (53 to 60%) and glutelins (19 to 25%) are the main protein fractions in chickpea, but albumins (8 to 12%), and prolamins (3 to 7%) are also relevant in it50. Although chickpea lacks sulfured amino acids52, it has low content of antinutritional factors and, consequently, high bioavailability of other essential amino acids14. Blend chickpea with other pulses that do not lack sulfured amino acids is an interesting solution to its limiting amino acids issue, so the quality of the protein in the final product increases significantly. Patent CA2982280 (A1) provided a method to produce an alternative to milk by using chickpea and/or pea protein as main ingredients. Moreover, the disclosed product has a smooth mouthfeel and does not necessarily need gum, emulsifier, or starch to be added to the formulation. On the other hand, EP3586644 (A1) and WO2020061698 (A1) focused on the production of pulse proteins, including chickpea. These proteins are stable both in hot and acid aqueous environments. Among chickpea proteins available in the market, finds the ones by Innovopro® and Atura®, which sell products with 70 and 80% protein contents, respectively75,76. The brand Green Boy® also has chickpea and other different plant-based proteins in its portfolio.

Other mixes

The group “other mixes” regards patents that used either seeds, nuts, legumes, pulses, cereals, seaweeds, fungus, or combinations of these elements. These combinations include blended products to reach a better amino acid score and to optimize the functional and sensorial features of final product. Such an outcome can be obtained through the interaction of proteins from different plant sources (Table 3).

FR3085826 (A3) disclosed a powder ready to be reconstituted in water or plant-based milk. This process uses proteins from peas, rice, oats, or from their mixes. Similarly, EP3429366 (A1) divulges a replacement for dairy milk, which is made of peanut protein—but it can also be made of cashew nut, almond, pea, oat, wheat, quinoa, or of combinations of these elements.

In regard to functional improvements, CN111227101 (A) provided an instant powdered beverage that can be composed of pea and rice proteins, which shows excellent solubility in hot water (≥85 °C). JPWO2013027813 (A1) presented a beer-like product with increased foam stability that was produced with protease, transglutaminase, and with one or more proteins from wheat, barley, corn, pea, or rice.

Focusing on sensorial aspects, WO2019228957 (A1) described a method to mask undesirable notes from beverages made of pea, wheat, or oat protein when ethyl cyclohexanoate was used as additive. EP3634146 (A1) suggested the application of ultrasound and membrane filtration processes in proteins from legumes, seeds, seaweeds, or fungus to obtain a clean taste and neutral color product that can be used to enrich a wide range of beverages.

A huge variety of blended products has been introduced in the market. The supplier Burcon® developed a combination of pea and canola proteins, which is nutritionally and functionally better than when these proteins are used separated. The brand Orgain® offers a blend of deffated peanut powder, pea protein, pumpkin seed protein, and almond protein77, while Manitoba Harvest® commercializes a mix of pea and hemp proteins, which is ideal to be added to smoothies or nondairy milks78.